Lockout Tagout (LOTO) safety tags are an essential part of industrial safety procedures designed to protect workers from serious injury or death resulting from the unexpected operation of machinery or equipment during maintenance or service.

Definition of Lockout Tagout

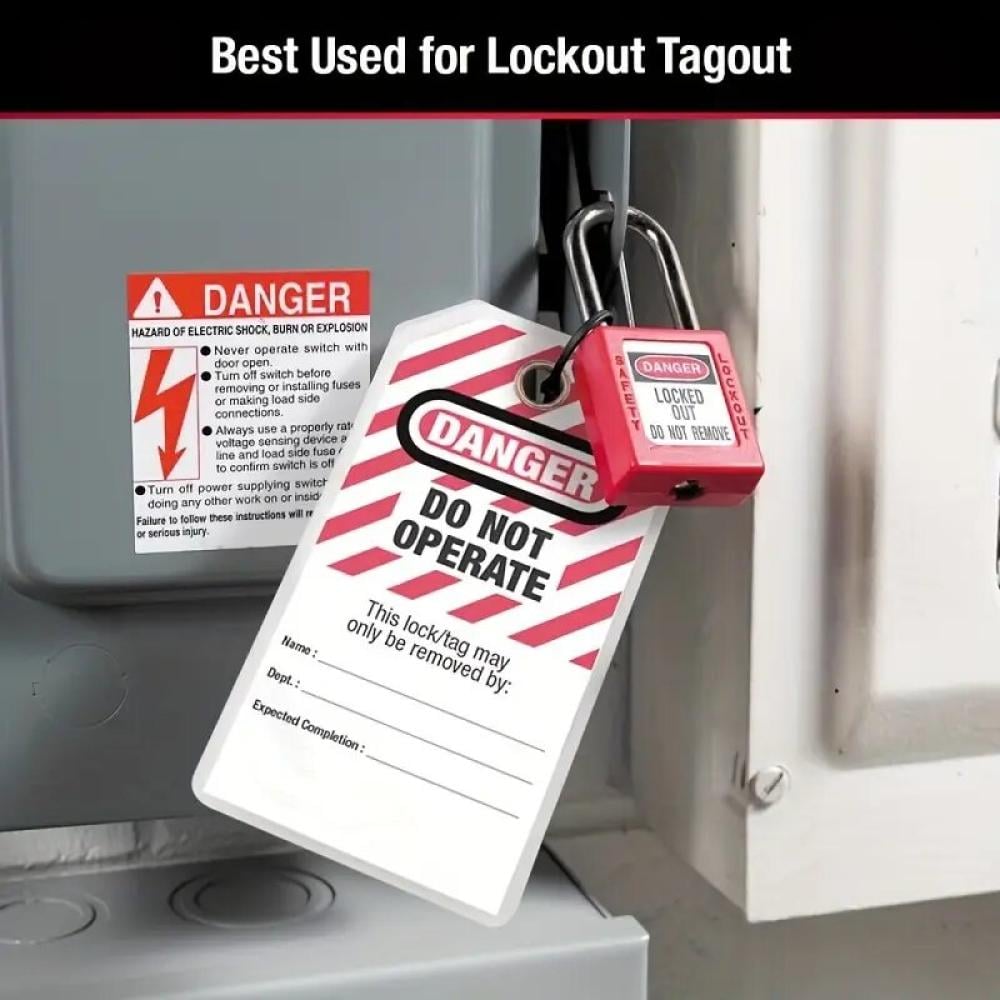

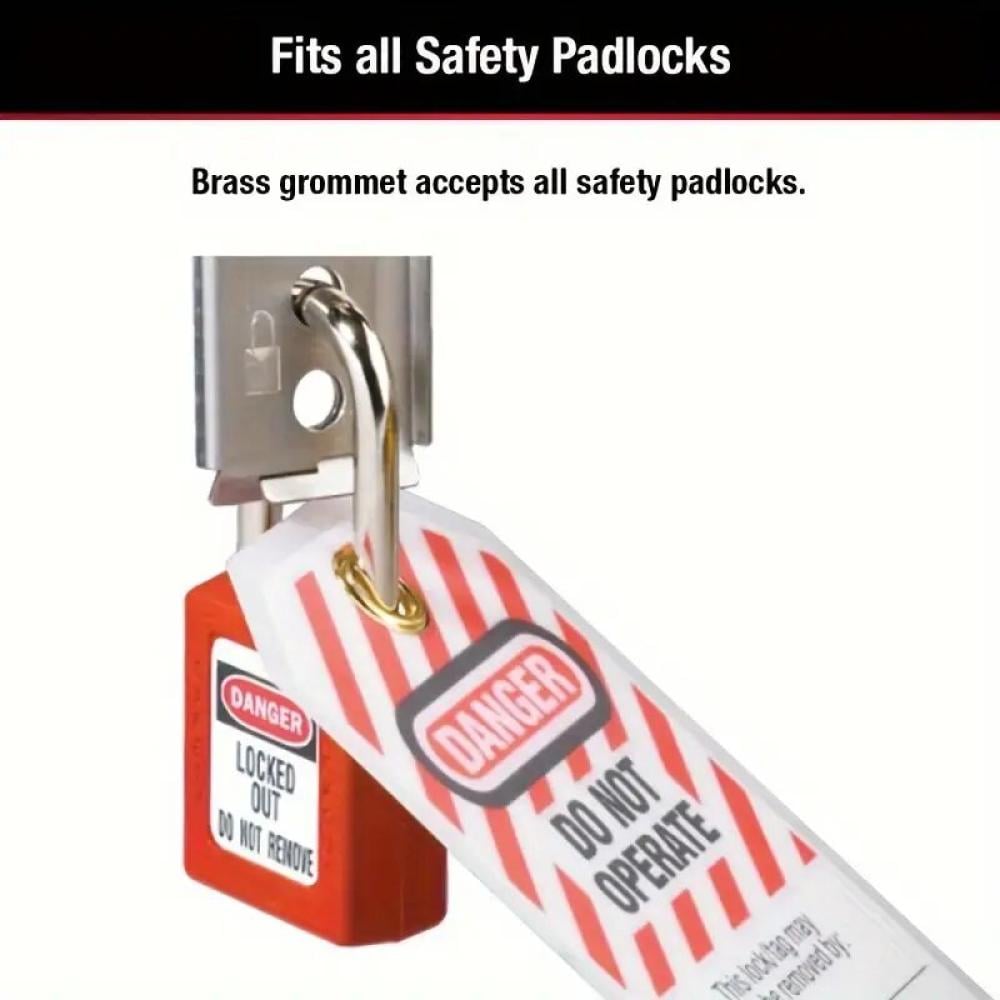

- Lockout: A physical procedure that involves placing a lock on a power source (such as a circuit breaker, pipeline valve, or electrical switch) to prevent it from being operated. This lockout ensures that the machine cannot be operated.

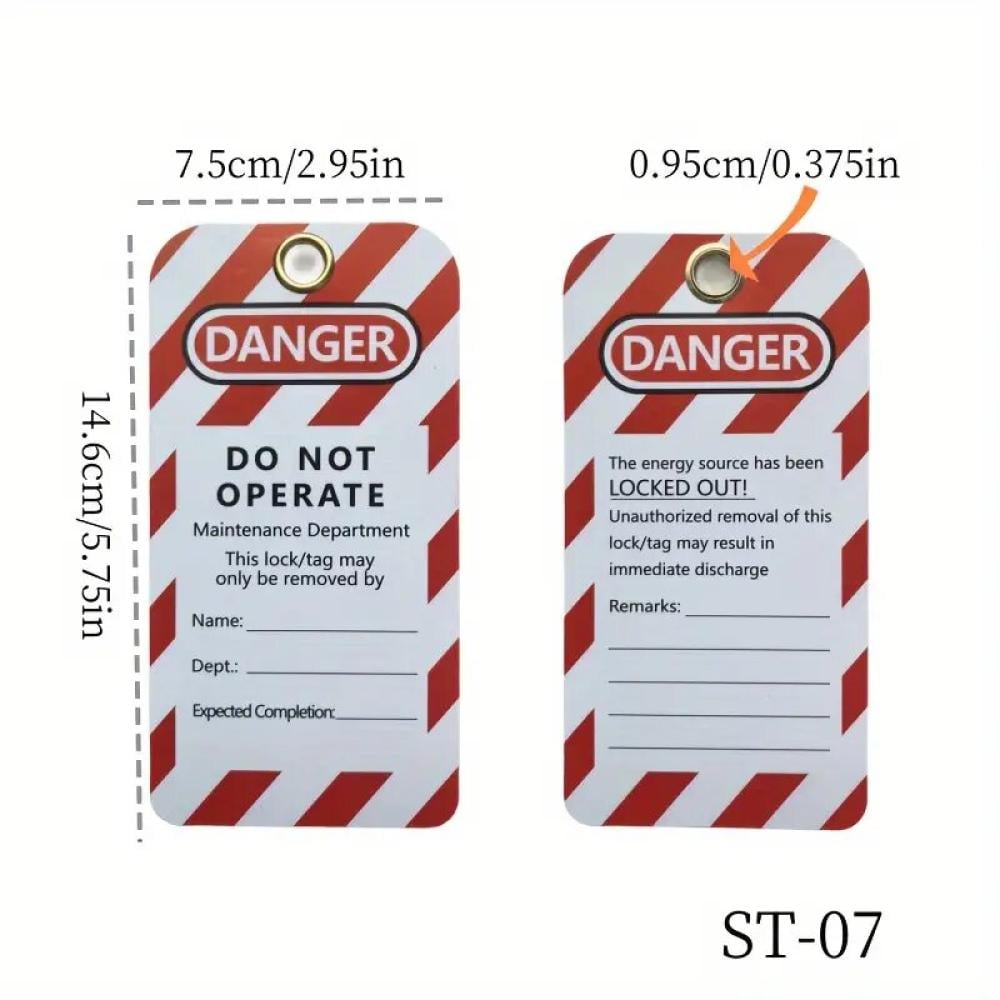

- Tagout: A procedure that complements a lockout involves placing a warning tag or tag on the locked power source. This tag contains important information such as:

- The reason for the equipment shutdown (maintenance, repair, cleaning).

- The name of the authorized person who applied the lockout and tagout.

- The date and time the procedure was applied.

- Clear warnings such as "Danger - Do Not Operate" or "Do Not Operate."

Uses of Safety Tagout Tags

- A safety tag does not function alone; it is part of an integrated system with the lockout. These tags are used in the following situations:

- Maintenance and Repair: When performing any maintenance or repair work on equipment, the equipment is shut down and isolated from its power source.

- Inspection and Cleaning: During routine inspections or cleaning of equipment containing moving parts or hazardous power sources.

- Any Unusual Operation: Whenever a worker needs to enter a hazardous area of the machine (such as to clear a blockage or adjust it).

- Benefits of Lockout Tagouts

- The entire LOTO system, including the tags, offers significant benefits to companies and employees:

- Life Protection: The most important benefit is protecting workers from injuries resulting from sudden equipment operation, such as electrocution, injury from moving parts, or exposure to hazardous chemicals.

- Safety Regulation Compliance: Ensures compliance with occupational safety standards, such as those set by the Occupational Safety and Health Administration (OSHA) in the United States, thus avoiding fines and legal penalties.

- Equipment Protection: The system prevents damage to expensive equipment resulting from unintended operation during maintenance.

- Improved communication: The tags serve as a clear visual communication tool, alerting workers in the area that equipment is unsafe to operate and is being serviced.

Promoting a safety culture: Implementing a strict LOTO system creates a safer work environment, increasing worker confidence and encouraging them to take proactive steps to protect themselves and their colleagues.