- Stainless Steel Eye Washer (often referred to as an Eyewash Station) is a critical piece of safety equipment designed to provide immediate flushing of the eyes and/or face with copious amounts of water in the event of exposure to hazardous materials. Stainless steel is a preferred material due to its durability, corrosion resistance, and hygienic properties, especially in environments where chemicals are present.

- Applications:

- Stainless steel eyewash stations are essential in any workplace where there's a risk of eye exposure to:

- Corrosive chemicals (acids, alkalis, solvents)

- Irritants (dust, fumes, particulate matter)

- Biological hazards

- Foreign bodies

- Heat (thermal burns)

- This includes:

- Chemical Manufacturing Plants

- Laboratories (research, academic, industrial)

- Petrochemical and Oil & Gas Industry

- Pharmaceutical Companies

- Food Processing Facilities

- Battery Charging Areas

- Mining Operations

- Construction Sites (especially those dealing with concrete admixtures, chemicals)

- Important Parameters:

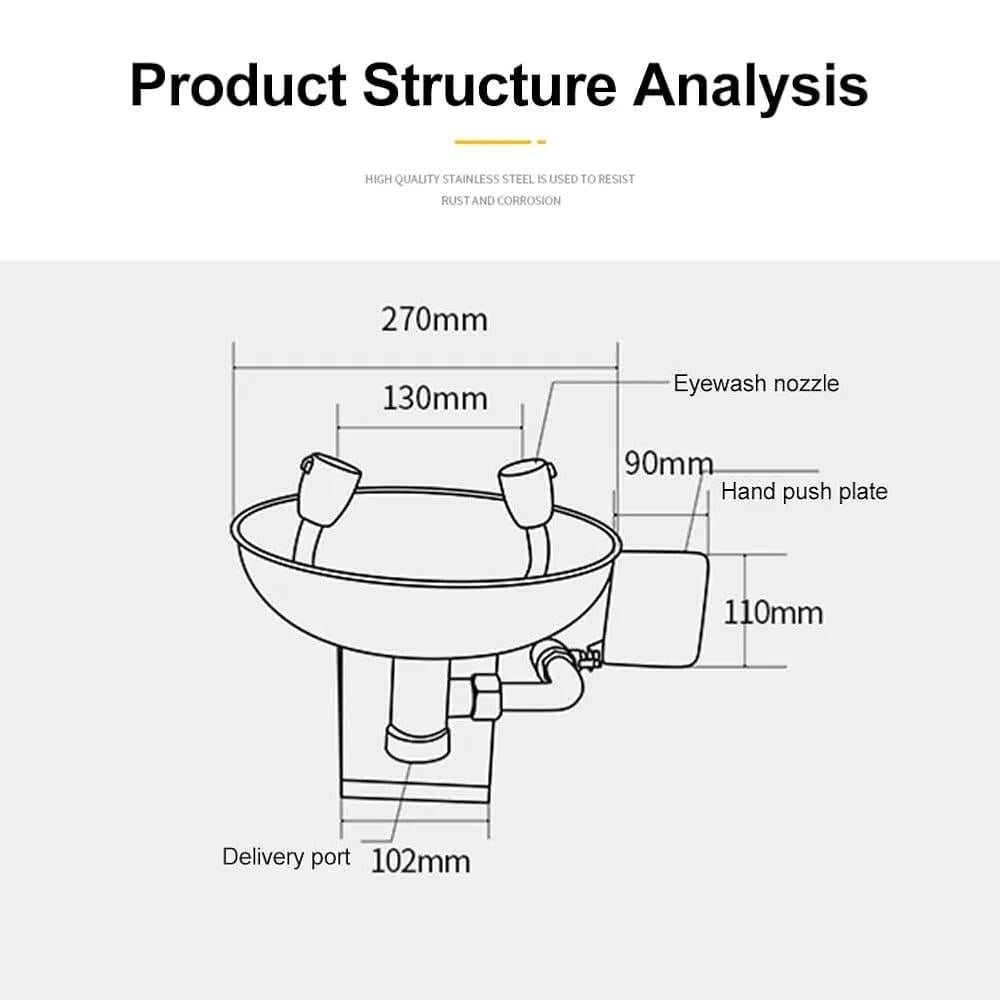

- Name: Stainless Steel Eye Washer

- Nominal pressure: 1.0Mpa

- Working pressure: 0.2—0.4Mpa

- Eyewash flow: >11.4L/min

- Inlet size: NPT1/2, the height of the water inlet changes with the installation height of the product

- Drain size: NPT1-1/4, the height of the drain varies with the installation height of the product

- Applicable conditions: Normal temperature water or water that meets sanitary standards

- Common Features across Stainless Steel Eyewashers:

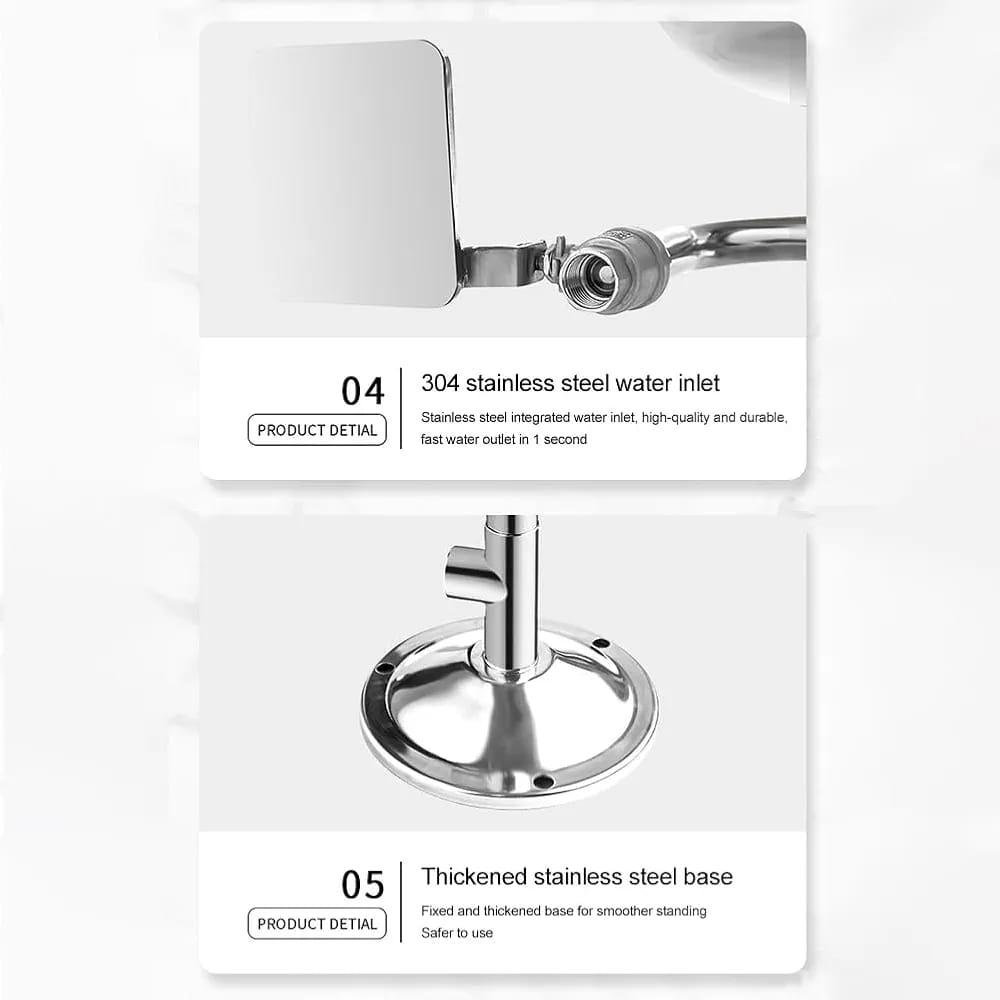

- Material: Primarily 304 Stainless Steel for good corrosion resistance, or 316 Stainless Steel for superior resistance in highly corrosive or saline environments (e.g., offshore oil rigs, specialized chemical plants).

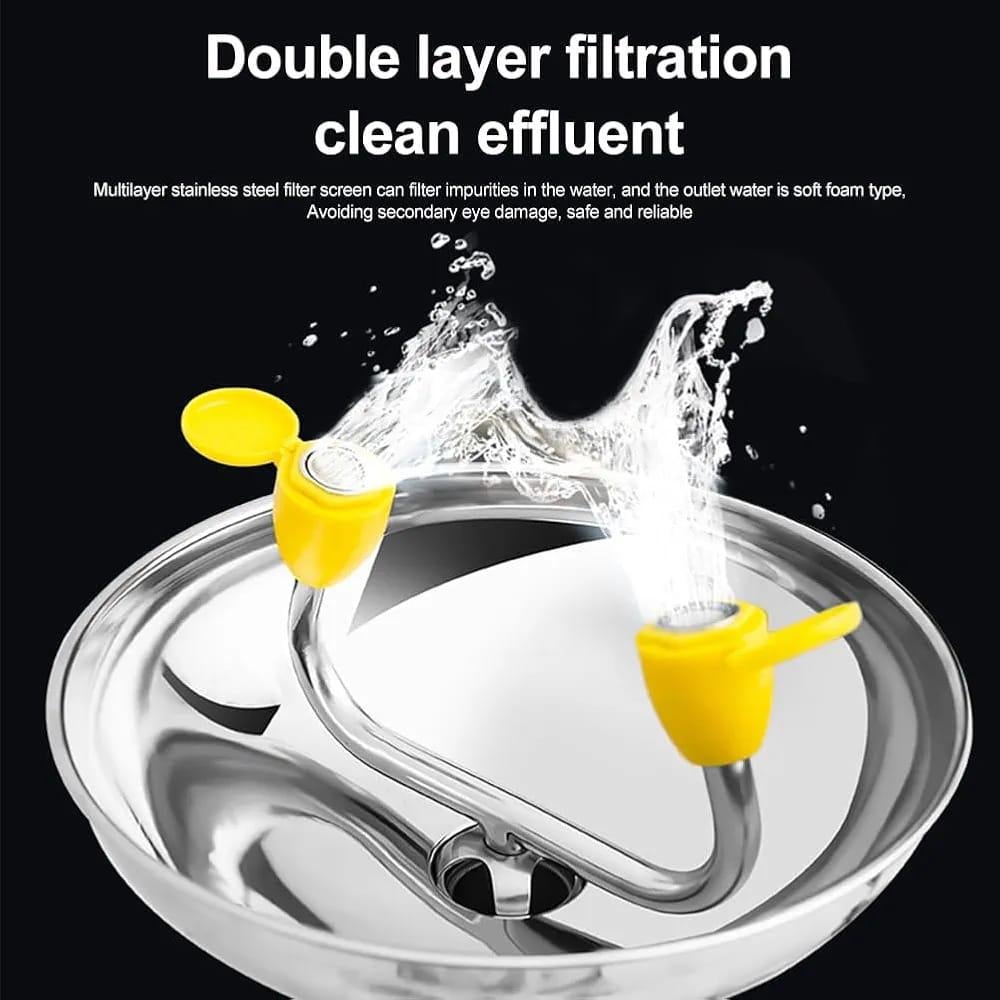

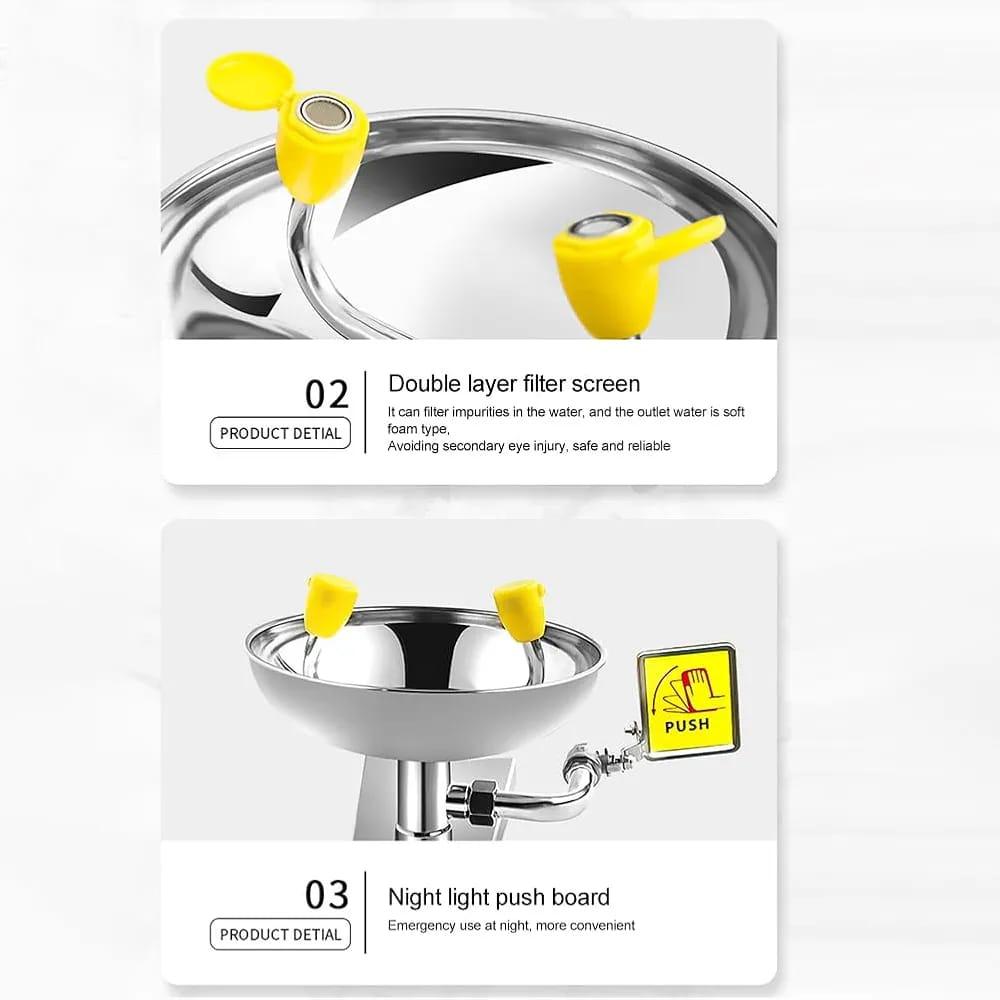

- Spray Heads: Typically two aerated spray heads that deliver a soft, controlled flow of water to effectively rinse the eyes and face without causing further injury. Often include dust covers to keep them clean.

- Valve: Stay-open ball valve mechanism ensures that once activated, the water flow continues without requiring the operator to hold the handle.

- Water Flow: Must deliver a minimum flow rate (e.g., 1.5 liters per minute for 15 minutes) as per ANSI Z358.1 standards.

- Visibility: Often comes with highly visible emergency signs.

- Compliance: Designed to meet international safety standards such as ANSI Z358.1-2014/2018 and OSHA requirements.

- Package Includes:

- 1 * Eyewash Station

- 1 * Accessories

- Product details

- Package Dimensions : 50 x 28 x 18 cm; 2.1 kg

- Made in: China