- An Emergency Eyewash Station, Combination Eyewash Station with Shower, and Eye and Face Wash Unit with Safety Shower, made of 304 Stainless Steel, and including an Eyewash Sign is a critical safety device designed to provide immediate decontamination in environments where individuals may be exposed to hazardous or corrosive materials.

- Here's a breakdown of its features, standards, and importance:

Key Features and Construction:

- Combination Unit: This type of station integrates both a safety shower and an eyewash/eye and face wash unit, allowing for full-body drenching or targeted flushing of the eyes and face.

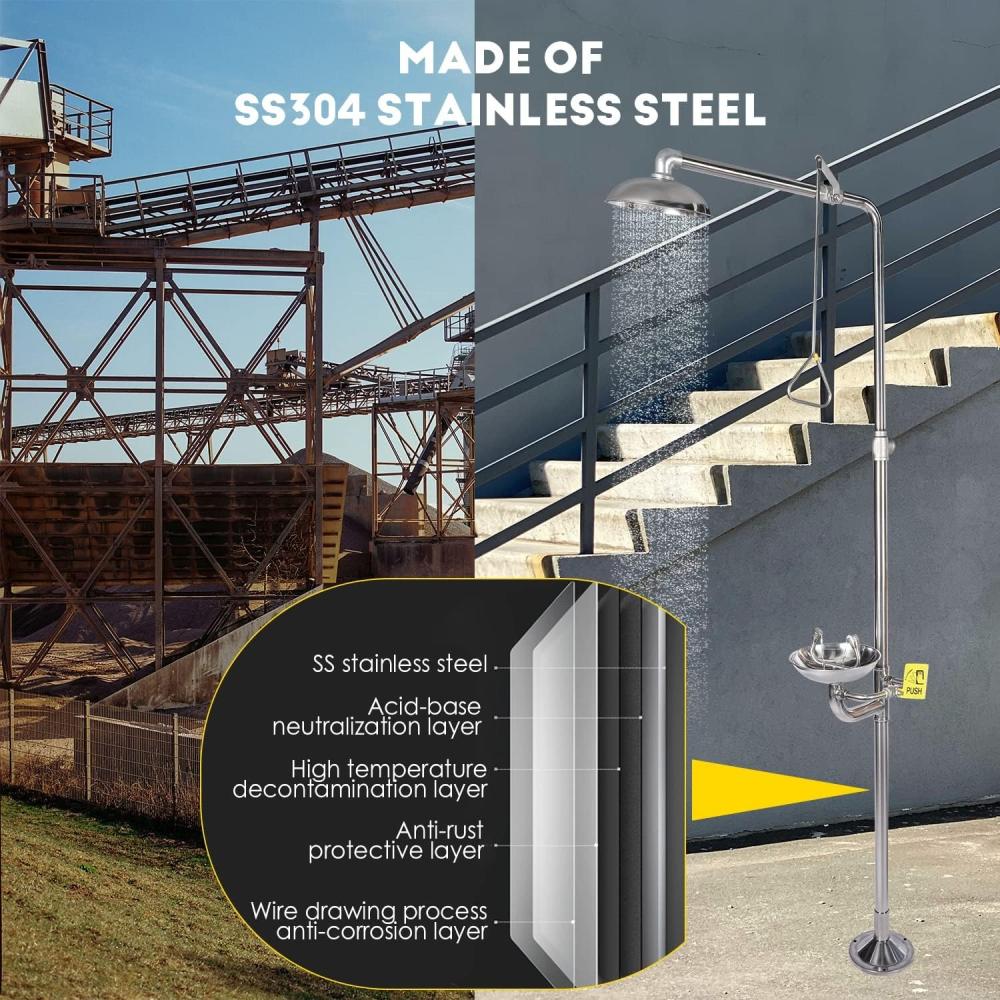

- 304 Stainless Steel Construction:

- Corrosion Resistance: 304 Stainless Steel is a common choice due to its excellent resistance to corrosion from a wide range of chemicals, acids, alkalis, salts, and oils. This makes it ideal for harsh industrial, chemical, laboratory, and coastal environments.

- Durability: It provides a robust and long-lasting solution, capable of withstanding demanding conditions.

- Hygiene: The smooth, polished surface of stainless steel is easy to clean and maintain.

Shower Head:

- High Flow Rate: Typically delivers a minimum flow of 75.7 liters per minute (20 GPM) for full-body decontamination.

Hydrodynamic Design:

- Many modern designs aim for an even distribution of water across the entire footprint of the flow, ensuring effective and comfortable rinsing.

Activation:

- Activated by a pull rod, designed for quick and easy operation.

- Eyewash/Eye and Face Wash:

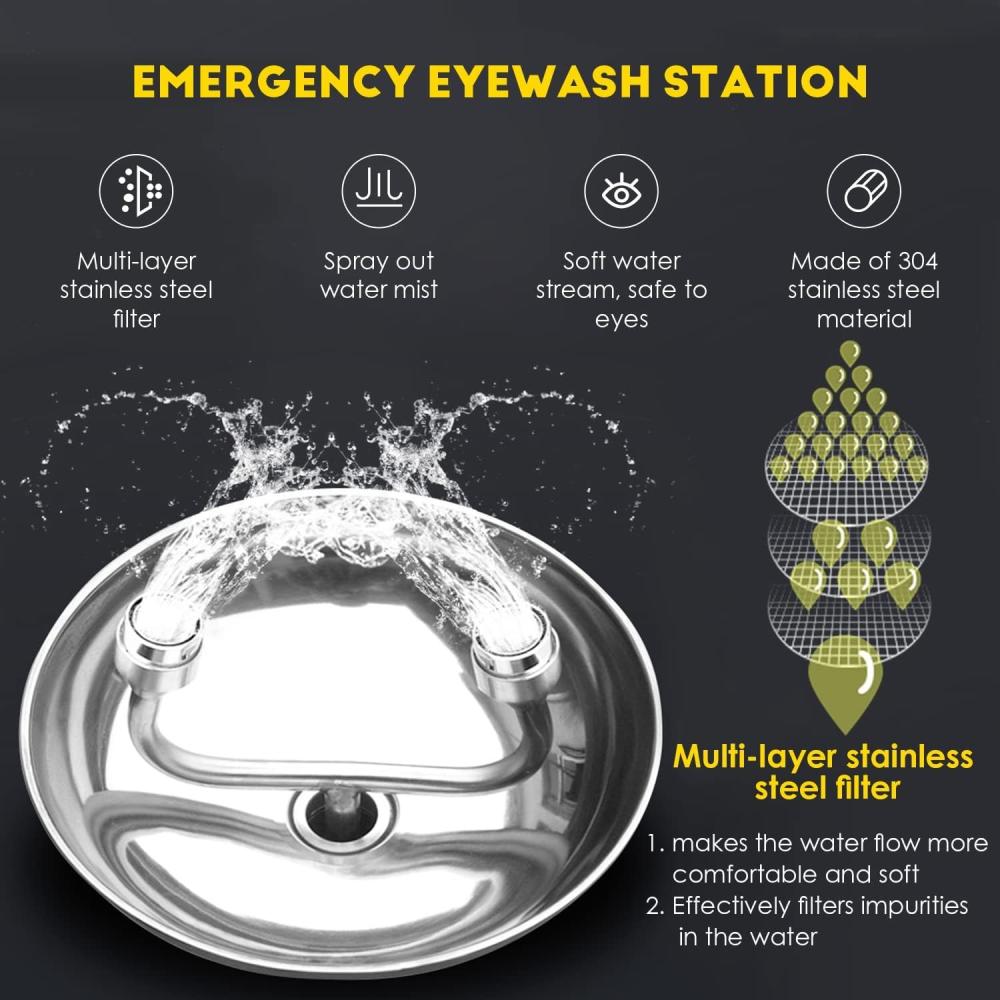

- Twin Spray Heads: Features two spray heads designed to deliver a gentle, aerated, and sufficient flow of water to both eyes simultaneously. Some advanced units use an "inverted directional laminar flow" to sweep contaminants away from the nasal cavity.

- Flow Rate: Provides a minimum flow of 1.5 liters per minute (0.4 GPM) for eyewash, and often higher (e.g., 11.4 L/min) for eye and face wash, for at least 15 minutes.

- Dust Covers: Integrated or easily removable dust covers protect the nozzles from airborne contaminants and debris, ensuring clean water delivery. These often automatically open when water flows.

- Bowl: An eye/face wash bowl, typically 304 stainless steel, collects the flushing fluid.

- Activation: Can be activated by a push handle, flag handle, or foot treadle for hands-free operation.

Applications:

- Combination eyewash and shower stations are essential in any workplace where there is a risk of chemical exposure to the eyes, face, or body. This includes:

- Chemical manufacturing and processing plants

- Laboratories (academic, research, industrial)

- Oil and gas facilities

- Pharmaceutical industries

- Battery charging areas

- Hazardous waste disposal sites

- Any area handling corrosive, caustic, or otherwise injurious materials.